Technical Info

General data

HOME > Technical Info > General data

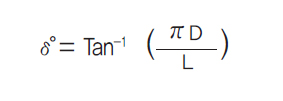

Nomenclature of Drill

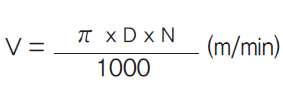

Machining formula

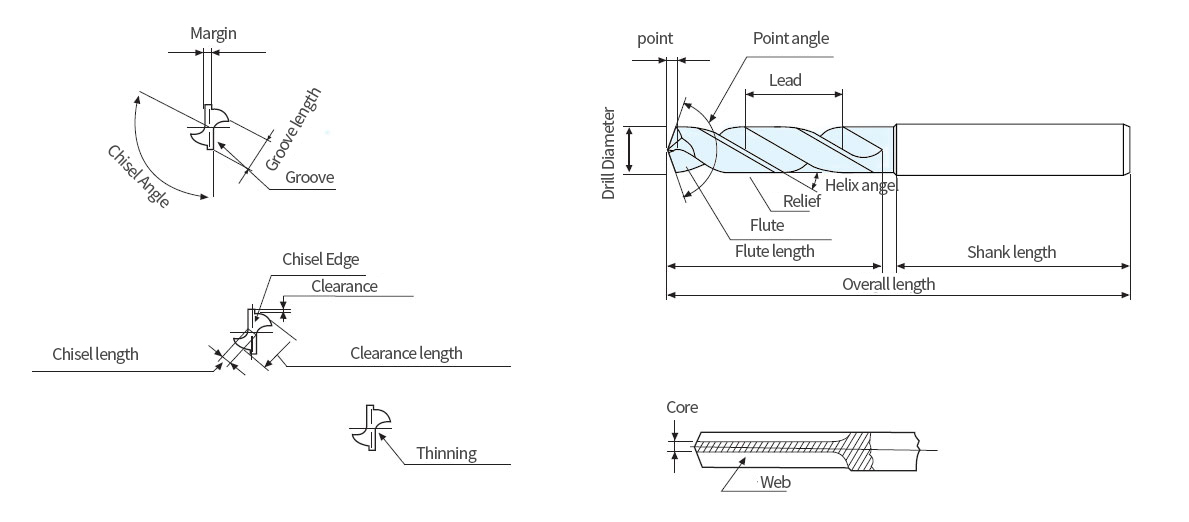

Working of Main Angle

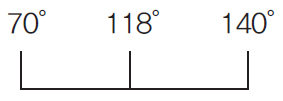

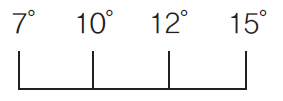

| Point Angle | Torsional Angle | Lip Relief Angle | |

|---|---|---|---|

Small → Thrust → Large |

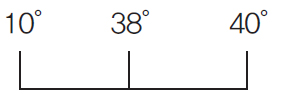

Good → Chip emission → Bad Large → Tool toughness → Small |

Small → Vibration → Large |

|

| Point Angle | Torsional Angle | Lip Relief Angle | |

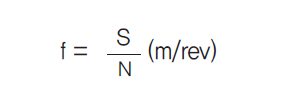

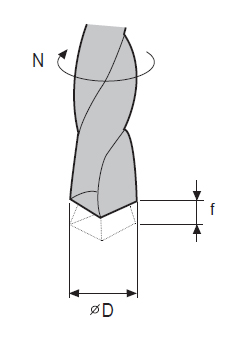

• D : Diameter of drill • N : Revolution • π : (3.14) (m/min) (mm) (rpm) |

• S : Depth of cut per min • N : Revolution (mm/rev) (mm/min) (rpm) |

• D : Diameter of drill • L : lead • π : (3.14) (mm) (mm) |

Drill Trouble Shooting

Drill Trouble Shooting

| Trouble issue | Cause | Solution |

|---|---|---|

| Drill does not enter the workpiece | Shortage of Lip Relief. Thick the Web. |

Regrinding to Lip Relief properly. Thin down the Web. |

| Margine chipping | Excessive Jig busing . | Using the suitable busing for Drill size. |

| Blance of cutting edge | Overheating the drill on work. | Reduce feed speed and supply with cutting oil sufficiently. |

| Chipping of cutting edge | Excessive rake angle. Excessive feed speed. |

Modify for Lip Relief. Reduce feed speed. |

| Broken of tang | Imperfection of connect between Taper shank and socket | Remove to socket alien substance or change to socket if it wear |

| Broken for brass work | Improper choice for Drill shape blockage the chip on groove point |

Choice to Drill properly |

| Crack of Drill core | Shortage of Flute Clearance. over feed speed |

Regrinding to Drill proper rake angle. Reduce feed speed. |

| Over hole size | Edge of flue angle and cutting length is different. Main shaft is loose |

Choice for good quality Drill. Tight up the Main shaft properly. |

| Broken for Flute edge | Over cutting speed Hard alien substance on workpiece Shortage of Drill tip Wear to Drill |

Grinding for tip properly. Reduce feed speed. Regrinding. |

| Irregular chip size | Edge of flue was wrong grinded or did work one side of flute. | Need to regrinding accurately. Choice for good quality drill. |

| Rough hole | Edge of flute was grinded as blunt or improperly. Unsupplied with cutting oil on Drill tip. Over feed speed Unsubstantial Tool holder. |

Regrinding to edge of flute angle. Supply with cutting oil properly. Reduce feed speed. Fix to Tool Holder solidly. |